硬密封法兰蝶阀 | D343H

硬密封法兰蝶阀 产品说明

硬密封法兰蝶阀D343H阀门密封组件为分体式,由阀板,阀座,阀座压环和压圈组成,阀座和阀座压环为可拆卸结构形式,在现场维修可直接拆卸更换新阀座即可,不用像整体式阀座的三偏心蝶阀那样整台阀门拆卸维修成本高昂,同时密封面处增加了研磨工艺,大大降低表面粗糙度,精度高,密封性好,适用于食品、冶金、医药、石油化工、电力、城市供热、供水、工业环保水处理、船舶等行业。

硬密封法兰蝶阀 技术参数

| 公称压力 Nominal pressure |

0.6MPa | 1.0MPa | 1.6MPa | 2.5MPa |

|---|---|---|---|---|

| 公称通径 Nominal diameter |

80~3000 mm |

80~3000 mm |

80~2000 mm |

80~1200 mm |

| 密封试验 Seal test |

0.66MPa | 1.1MPa | 1.76MPa | 2.75MPa |

| 壳体强度试验 Shell strength tes |

0.9MPa | 1.5MPa | 2.4MPa | 3.75MPa |

| 适用温度 Applicable temperature |

≤100℃~600℃ | |||

| 适用介质 Applicable medium |

烟气、热水、蒸汽、煤气、酸、碱、食品 Flue gas, hot water, steam,gas, acld, alkall,food | |||

| 驱动形式 Driving form |

蜗轮传动、电动、气动 Worm gear drive,electric,pneumatic |

|||

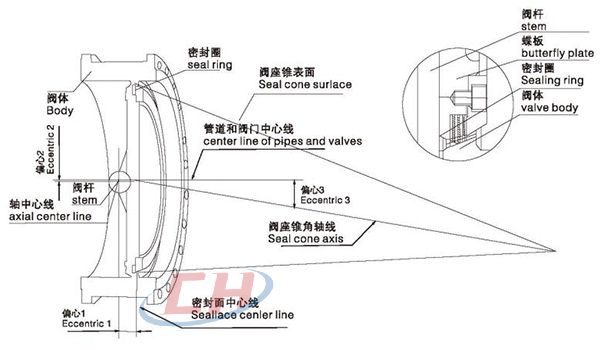

偏心结构示意图

硬密封法兰蝶阀 材质

| 阀体 valve body |

铸钢、不锈钢、球墨铸铁 Cast steel, stainless steel, ductile cast iron |

|---|---|

| 阀座 valve seat |

不锈钢 stainless steel |

| 蝶板 Disc |

铸钢、不锈钢、球墨铸铁 Cast steel, stainless steel, ductile cast iron |

| 密封圈 sealring |

不锈钢、橡胶 Stainless steel, rubber |

| 阀杆 stem |

2Cr13不锈钢、1Cr13不锈钢、45#钢 2Cr13 stainless steel,1Cr13 stainless steel, 45#steel |

| 衬套 bushing |

铸钼青铜自润轴承 Cast molybdenum bronze self lubrication bearing |

硬密封法兰蝶阀 结构尺寸图

硬密封法兰蝶阀 连接尺寸

| 通径 | 1.0MPa | |||||

|---|---|---|---|---|---|---|

| DN | L | D | D1 | D2 | H | Z-φd |

| 80 | 114 | 200 | 160 | 132 | 310 | 8-18 |

| 100 | 127 | 220 | 180 | 156 | 325 | 8-18 |

| 125 | 140 | 250 | 210 | 184 | 360 | 8-18 |

| 150 | 140 | 285 | 240 | 211 | 395 | 8-22 |

| 200 | 152 | 340 | 295 | 266 | 480 | 8-22 |

| 250 | 165 | 395 | 350 | 319 | 550 | 12-22 |

| 300 | 178 | 445 | 400 | 370 | 610 | 12-22 |

| 350 | 190 | 505 | 460 | 429 | 710 | 16-22 |

| 400 | 216 | 565 | 515 | 480 | 755 | 16-26 |

| 450 | 222 | 615 | 565 | 530 | 835 | 20-26 |

| 500 | 229 | 670 | 620 | 582 | 900 | 20-26 |

| 600 | 267 | 780 | 725 | 682 | 1060 | 20-30 |

| 700 | 292 | 895 | 840 | 794 | 1170 | 24-30 |

| 800 | 318 | 1015 | 950 | 901 | 1320 | 24-33 |

| 900 | 330 | 1115 | 1050 | 1001 | 1440 | 28-33 |

| 1000 | 410 | 1230 | 1160 | 1112 | 1640 | 28-36 |

| 1200 | 470 | 1455 | 1380 | 1328 | 1720 | 32-39 |

| 1400 | 530 | 1675 | 1590 | 1530 | 2010 | 36-42 |

| 1600 | 600 | 1915 | 1820 | 1750 | 2255 | 40-48 |

| 1800 | 670 | 2115 | 2020 | 1950 | 2480 | 44-48 |

| 2000 | 760 | 2235 | 2230 | 2150 | 2660 | 48-48 |

| 2200 | 800 | 2500 | 2440 | 2370 | 3750 | 52-56 |

| 2400 | 850 | 2760 | 2650 | 2570 | 4350 | 56-56 |

| 2600 | 900 | 2960 | 2850 | 2770 | 4600 | 60-56 |

| 2800 | 950 | 3290 | 3050 | 2980 | 4900 | 64-64 |

| 3000 | 1000 | 3500 | 3250 | 3200 | 5300 | 64-68 |

| 通径 | 1.6MPa | |||||

|---|---|---|---|---|---|---|

| DN | L | D | D1 | D2 | H | Z-φd |

| 80 | 114 | 200 | 160 | 132 | 310 | 8-18 |

| 100 | 127 | 220 | 180 | 156 | 325 | 8-18 |

| 125 | 140 | 250 | 210 | 184 | 360 | 8-18 |

| 150 | 140 | 285 | 240 | 211 | 395 | 8-22 |

| 200 | 152 | 340 | 295 | 266 | 480 | 12-18 |

| 250 | 165 | 405 | 355 | 319 | 550 | 12-26 |

| 300 | 178 | 460 | 410 | 370 | 610 | 12-26 |

| 350 | 190 | 520 | 470 | 429 | 710 | 16-26 |

| 400 | 216 | 580 | 525 | 480 | 755 | 16-30 |

| 450 | 222 | 640 | 585 | 548 | 835 | 20-30 |

| 500 | 229 | 715 | 650 | 609 | 900 | 20-33 |

| 600 | 267 | 840 | 770 | 720 | 1060 | 20-36 |

| 700 | 292 | 910 | 840 | 794 | 1170 | 24-36 |

| 800 | 318 | 1025 | 950 | 901 | 1320 | 24-39 |

| 900 | 330 | 1125 | 1050 | 1001 | 1440 | 28-39 |

| 1000 | 410 | 1255 | 1170 | 1112 | 1640 | 28-42 |

| 1200 | 470 | 1485 | 1390 | 1328 | 1850 | 32-48 |

| 1400 | 530 | 1685 | 1590 | 1530 | 2040 | 36-48 |

| 1600 | 600 | 1930 | 1820 | 1750 | 2280 | 40-55 |

| 1800 | 670 | 2130 | 2020 | 1950 | 2495 | 44-55 |

| 2000 | 760 | 2345 | 2230 | 2150 | 2685 | 48-60 |